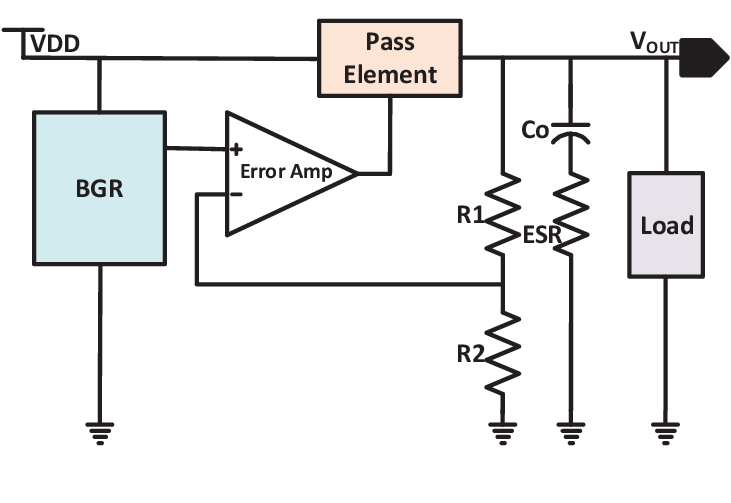

While working on LDO, ensuring stable LDO operation is very important. When we say stable operation, the output must have desired voltage output without any oscillations. The main culprit behind instability in an LDO (Low Dropout) regulator is often the interaction between the regulator’s control loop and the output capacitor’s characteristics, especially the output capacitor's equivalent series resistance (ESR).

LDOs typically use a PNP or PMOS as series pass element, which introduces a pole at a relatively low frequency in the control loop. To maintain stability, the loop needs a zero to counteract that pole and this is where the ESR of the output capacitor comes in. If the ESR is too low (as with many modern ceramic capacitors), the zero may be too high in frequency or absent altogether, leading to poor phase margin and potential oscillations.

Datasheet recommends the output capacitor value based on this criteria. Some datasheets even have application circuit with output capacitor MPN recommended. They must have tested the LDO under various conditions and suggested this capacitor. So, if designers ignores this recommendation and goes with a best capacitor option like lowest ESR as per our design knowledge, there is every chance that LDO might be unstable. So, ironically, using a “better” capacitor (with lower ESR) can sometimes make things worse unless the LDO is specifically designed to handle it. That’s why datasheets often recommend specific capacitor types and values.

This is a simple case to explain the need for following datasheet recommendations. Interestingly, designers who follow datasheet recommendations blindly might end up with a best design than the engineers who use their design skills, intuition to come up with the circuit.

0 Comments